TuningGoal.Poles

Constraint on control system dynamics

Description

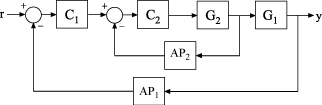

Use TuningGoal.Poles to constrain the closed-loop

dynamics of a control system or of specific feedback loops within the control system. You can use

this tuning goal for control system tuning with tuning commands, such as

systune or looptune. A TuningGoal.Poles goal can ensure a minimum decay rate or minimum damping of the poles

of the control system or loop. It can also eliminate fast dynamics in the tuned

system.

Creation

Syntax

Description

Req = TuningGoal.Poles(mindecay,mindamping,maxfreq)mindecay = 0,

mindamping = 0, or maxfreq = Inf

to skip any of the three constraints.

Req = TuningGoal.Poles(location,mindecay,mindamping,maxfreq)getSensitivity (Simulink Control Design) for information about

sensitivity functions.) Use this syntax to narrow the scope of the tuning goal to a particular

feedback loop.

If you want to constrain the poles of the system with one or more feedback loops opened,

set the Openings property. To limit the enforcement of this tuning goal to

poles having natural frequency within a specified frequency range, set the

Focus property. (See Properties.)

Input Arguments

Properties

Examples

Tips

TuningGoal.Polesrestricts the closed-loop dynamics of the tuned control system. To constrain the dynamics or ensure the stability of a single tunable component, useTuningGoal.ControllerPoles.

Algorithms

When you tune a control system using a TuningGoal, the software converts

the tuning goal into a normalized scalar value f(x).

x is the vector of free (tunable) parameters in the control system. The

software then adjusts the parameter values to minimize

f(x), or to drive

f(x) below 1 if the tuning goal is a hard

constraint.

For TuningGoal.Poles,

f(x) reflects the relative satisfaction or violation of

the goal. For example, if you attempt to constrain the closed-loop poles of a feedback loop to a

minimum damping of ζ = 0.5, then:

f(x) = 1 means the smallest damping among the constrained poles is ζ = 0.5 exactly.

f(x) = 1.1 means the smallest damping ζ = 0.5/1.1 = 0.45, roughly 10% less than the target.

f(x) = 0.9 means the smallest damping ζ = 0.5/0.9 = 0.55, roughly 10% better than the target.

Version History

Introduced in R2012bSee Also

looptune | systune | looptune (for slTuner) (Simulink Control Design) | systune (for slTuner) (Simulink Control Design) | viewGoal | evalGoal | tunableTF | tunableSS | TuningGoal.ControllerPoles