PMSM (Five-Phase)

Five-phase permanent magnet synchronous motor with sinusoidal flux distribution

Libraries:

Simscape /

Electrical /

Electromechanical /

Permanent Magnet

Description

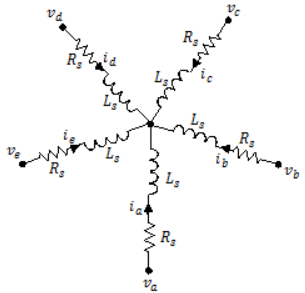

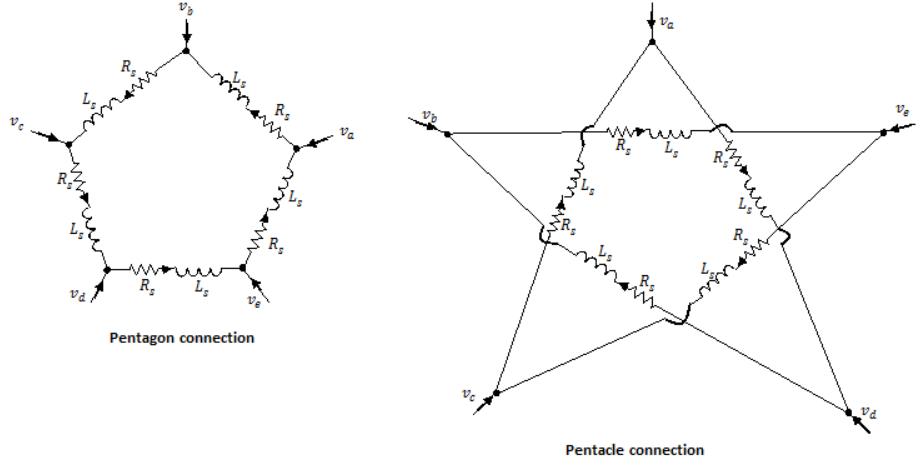

The PMSM (Five-Phase) block models a permanent magnet synchronous motor (PMSM) with a five-phase star-wound, pentagon-wound, or pentacle-wound stator. Use this block to model these types of motor if the motor has five stator windings: an interior permanent magnet synchronous machine (IPMSM), surface permanent magnet synchronous machine (SPMSM), axial flux (pancake) motor, or PMSM servomotor. The figure shows the equivalent electrical circuit for the star-connected stator windings.

You can also model the permanent magnet synchronous motor either in a

pentagon-wound or a pentacle-wound configuration by setting Winding

type to Pentagon-wound or

Pentacle-wound.

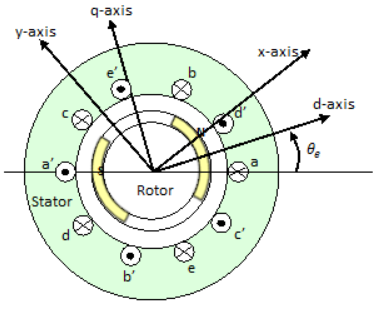

Motor Construction

This figure shows the motor construction with a single pole-pair on the rotor.

Permanent magnets generate a rotor magnetic field that creates a sinusoidal rate of change of flux based on the rotor angle.

For the axes convention, when you set the Rotor angle

definition parameter to Angle between the a-phase

magnetic axis and the d-axis, the a-phase and

permanent magnet fluxes align when the rotor mechanical angle,

θr, is zero. When you set the

Rotor angle definition parameter to Angle

between the a-phase magnetic axis and the q-axis, the rotor

mechanical angle is the angle between the a-phase magnetic axis

and the rotor q-axis.

Equations

The voltages across the stator windings are

where:

va, vb, vc, vd, and ve are the individual phase voltages across the stator windings.

Rs is the equivalent resistance of each stator winding.

ia, ib, ic, id, and ie are the currents flowing in the stator windings.

and are the rates of change for the magnetic flux in each stator winding.

The permanent magnet and the five windings contribute to the total flux linking each winding. The total flux is

where:

ψa, ψb, ψc, ψd, and ψe are the total fluxes that link each stator winding.

Laa, Lbb, Lcc, Ldd, and Lee are the self-inductances of the stator windings. These self-inductances are a function of the rotor electrical angle, θe, and depend on the stator per-phase self-inductance, Ls, and the stator inductance fluctuation, Lm.

where θr is the rotor mechanical angle.

rotor offset is

pi/2if you define the rotor electrical angle with respect to the d-axis, or0if you define the rotor electrical angle with respect to the q-axis.Ls is the stator per-phase self-inductance. This value is the average self-inductance of each of the stator windings.

Lm is the stator inductance fluctuation. This value is the amount the self-inductance and mutual inductance fluctuate with the changing of the rotor angle.

Lab, Lac, Lba, and so on, are the mutual inductances of the stator windings. These mutual inductances are a function of the rotor electrical angle, θe, and depend on the stator mutual inductance, Ms, and the stator per-phase self-inductance, Ls.

Ms is the stator mutual inductance. This value is the average mutual inductance between the stator windings.

ψam, ψbm, ψcm, ψdm, and ψem are the permanent magnet fluxes linking the stator windings.

The permanent magnet flux linking winding a-a' is at maximum when θe = 0° and zero when θe = 90°. Therefore, the linked motor flux is defined by:

where ψm is the permanent magnet flux linkage.

Simplified Electrical Equations

To remove the rotor angle dependence for the inductive terms, you perform a transformation, T, on the motor equations.

The T transformation is defined by:

where θe is the electrical angle defined as Nθr. N is the number of pole pairs.

The transformation matrix has this pseudo-orthogonal property:

Using the T transformation on the stator winding voltages and currents transforms them to the dq0 and xy frames, which are independent of the rotor angle:

Applying this transformation to the first two electrical equations produces these equations

where:

Ld = Ls + Ms + 5/2 Lm. Ld is the stator d-axis inductance.

Lq = Ls + Ms − 5/2 Lm. Lq is the stator q-axis inductance.

L0 = Ls – 4Ms. L0 is the stator zero-sequence inductance.

ω is the rotor mechanical rotational speed.

N is the number of rotor permanent magnet pole pairs.

Alternative Flux Linkage Parameterization

You can parameterize the motor by using the back EMF or torque constants, which are more commonly given on motor datasheets, by using the Permanent magnet flux linkage parameter.

The back EMF constant is the peak voltage induced by the permanent magnet in the per-unit rotational speed of each of the phases. The relationship between the peak permanent magnet flux linkage and the back EMF is:

The back EMF, eph, for one phase is:

The torque constant is the peak torque induced by the per-unit current of each of the phases. It is numerically identical in value to the back EMF constant when both are expressed in SI units:

When Ld = Lq and the currents in all five phases are balanced, the combined torque T is:

where Ipk is the peak current in any of the three windings.

The factor 5/2 is calculated from the steady-state sum of the torques from all phases. Therefore, the torque constant kt can also be:

where T is the measured total torque when testing with a balanced three-phase current with a peak line voltage of Ipk. The RMS line voltage is:

Model Thermal Effects

You can expose thermal ports to model the effects of losses that convert power to heat. To expose the thermal ports, set the Modeling option parameter to either:

No thermal port— The block contains expanded electrical conserving ports associated with the stator windings, but does not contain thermal ports.Show thermal port— The block contains expanded electrical conserving ports associated with the stator windings and thermal conserving ports for each of the windings and for the rotor.

For more information about using thermal ports in actuator blocks, see Simulating Thermal Effects in Rotational and Translational Actuators.

Variables

To set the priority and initial target values for the block variables before simulation, use the Initial Targets section in the block dialog box or Property Inspector. For more information, see Set Priority and Initial Target for Block Variables.

Nominal values provide a way to specify the expected magnitude of a variable in a model. Using system scaling based on nominal values increases the simulation robustness. You can specify nominal values using different sources, including the Nominal Values section in the block dialog box or Property Inspector. For more information, see System Scaling by Nominal Values.

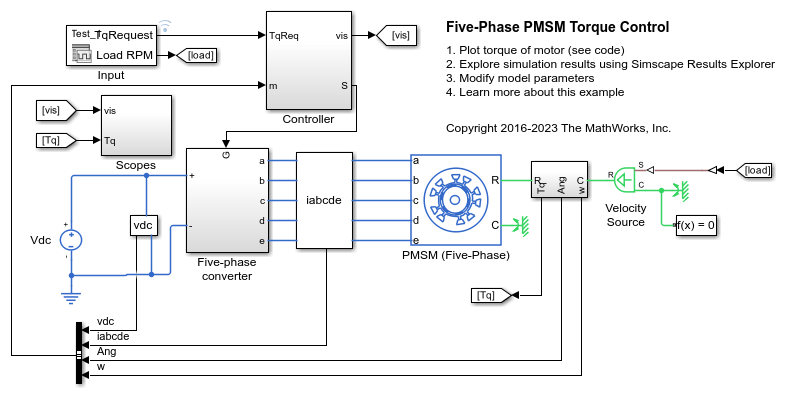

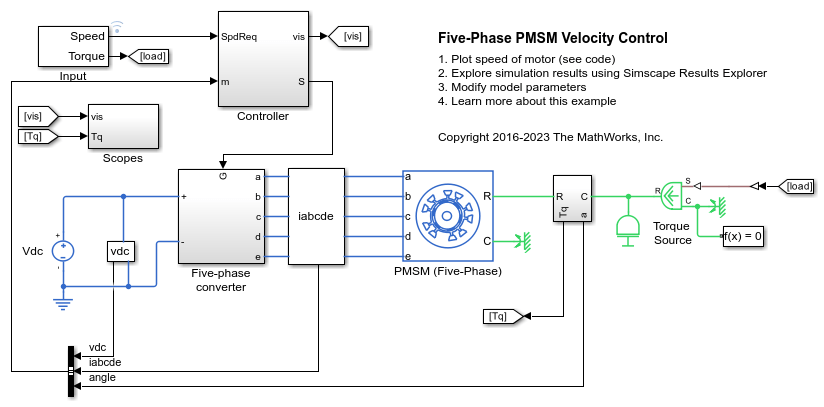

Examples

Ports

Conserving

Parameters

References

[1] L. Parsa and H. A. Toliyat. Sensorless Direct Torque Control of Five-Phase Interior Permanent-Magnet Motor Drives. IEEE Transactions on Industry Applications, vol. 43, no. 4, pp.952-959, July–Aug., 2007.

[2] Anderson, P. M. Analysis of Faulted Power Systems. IEEE Press Power Systems Engineering Series, 1995. ISBN 0-7803-1145-0.