Automotive

In this section, you can find examples of automotive systems in multiple Simscape Fluids domains.

Featured Examples

ABS Open Loop Test Bench

A simple way of modeling of the anti-lock braking system (ABS) and using it with the manual braking components. The model simulates for the open loop ABS and shows the response of the pressures achieved in the caliper disc brakes. This model can be utilized in sizing of the release valve, apply valve and accumulator for the hydraulic control unit of the ABS.

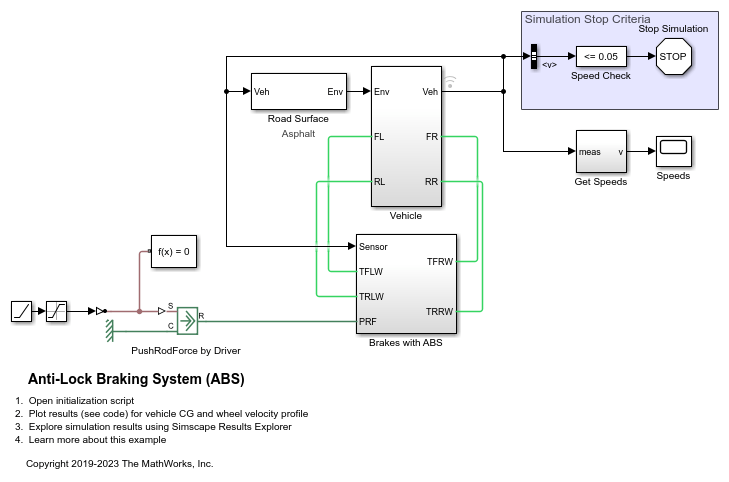

Anti-Lock Braking System (ABS)

A simple way of modeling an ABS braking system. The model shows the velocity profile responses achieved for the vehicle CG and the wheels.

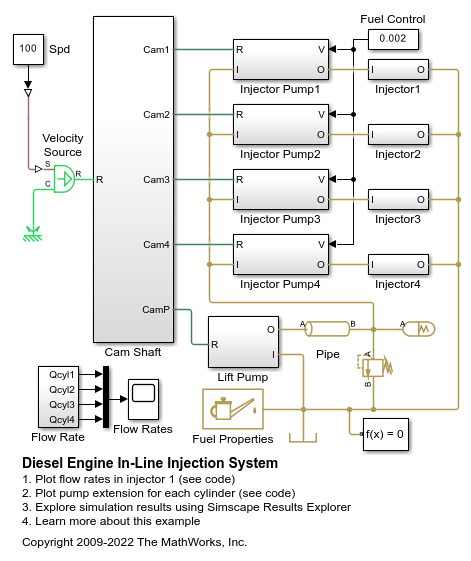

Diesel Engine In-Line Injection System

An in-line multi-element diesel injection system. It consists of a cam shaft, a lift pump, four in-line injection pumps, and four injectors.

Diesel Engine In-Line Injection System

Warning: This example uses the hydraulic domain, which will be removed in a future release. Find an equivalent example model that uses the isothermal liquid domain here: Diesel Engine In-Line Injection System. To convert models to the isothermal liquid domain, use the hydraulicToIsothermalLiquid tool.

Electric Vehicle Thermal Management

Model the thermal management system of a battery electric vehicle.

EV Battery Cooling System

This demo shows an Electric Vehicle (EV) battery cooling system. The battery packs are located on top of a cold plate which consists of cooling channels to direct the cooling liquid flow below the battery packs. The heat absorbed by the cooling liquid is transported to the Heating-Cooling Unit. The Heating-Cooling Unit consists of three branches to switch operating modes to cool and heat the battery. The Heater represents an electrical heater for fast heating of the batteries under low temperature conditions. The Radiator uses air-cooling and/or heating when the batteries are operated stably. The Refrigerant system is used for cooling the overheated batteries. The refrigeration cycle is represented by the amount of heat flow extracted from the cooling liquid. The system is simulated under either FTP-75 drive cycle or fast charge scenarios with different environment temperatures.

EV Battery Cooling System Design

Explores several questions related to heat exchanger sizing and system performance. The example answers the questions using fundamental heat transfer principles, and then confirms the behavior in test harness models and a full system model.

Electric Vehicle Thermal Management with Heat Pump

Models the thermal management system of a battery electric vehicle (BEV) that includes a heat pump for cabin heating. The system consists of two liquid coolant loops, a refrigerant loop, and a cabin air HVAC loop. The thermal loads are the batteries, the powertrain, and the cabin.

Electro-Hydraulic Limited Slip Differential

A simple way of modeling an electro-hydraulic limited slip differential system. The model shows the velocity and the torque profile responses achieved for the left and the right wheels.

Hydraulic Clutch System

Model, parameterize, and test a hydraulic clutch system. The model is used to generate the plot of the engine and the transmission system speeds during a declutching and clutch re-engaging scenario.

Hydrostatic CVT

Model, parameterize, and test a hydrostatic continuously variable transmission (CVT) with a swash angle shift command. When you run the plot function, it generates a comparison plot between the engine and the achieved rotational velocity in the hydraulic axial piston motor with respect to the time. Construction and agricultural equipment manufacturers use these transmissions.

Hydrostatic Transmission

A hydraulic transmission system built of a variable-displacement pump and a fixed-displacement motor. The pipes between the pump and the motor are connected by two replenishing valves (check valves) and a charge pump on the pump side and two pressure relief valves on the motor side. The motor drives a mechanical load consisting of an inertia, viscous friction, and time-varying torque. The system is tested with both positive and negative pump flow rate by varying the pump displacement.

Hydrostatic Transmission

Warning: This example uses the hydraulic domain, which will be removed in a future release. Find an equivalent example model that uses the isothermal liquid domain here: Hydrostatic Transmission. To convert models to the isothermal liquid domain, use the hydraulicToIsothermalLiquid tool.

Hydrostatic Transmission with Shuttle Valve

A hydrostatic transmission with a control unit that uses a shuttle valve. In the control unit, the valve actuator controls the 4-way directional valve that connects the motor to the pressure line. When one or both of the two 3-way directional valves (Shuttle A Valve and Shuttle A1 Valve) open, the shuttle valve applies force to the valve actuator so that the 4-way valve connects the motor to the pressure line. A fixed orifice is connected to the P ports of the 3-way directional valves to decrease flow consumption of the control unit. Another fixed orifice models a small leak from the valve actuator, which prevents the control unit from being isolated from the main flow.

Hydrostatic Transmission with Secondary Control

Demonstrates the use of secondary control for a hydrostatic transmission with a pressure-compensated pump and a variable-displacement motor. The transmission drives a winch that lifts a mass and acts against a viscous damper. The secondary control unit introduces closed-loop control with angular velocity feedback. It contains a servo-cylinder controlled by a proportional 4-way valve, and the servo-cylinder controls the motor's control member, which is represented by a mass, spring, and damper. The dynamic compensator in the model improves system stability.

Power-Assisted Steering Mechanism

A simplified version of a power-assisted steering mechanism. The hydraulic actuation system includes a double-acting hydraulic cylinder, 4-way valve, fixed-displacement pump, and a pressure-relief valve. The steering rack acts against a load modeled by a spring and damper.

Power-Assisted Steering Mechanism

Warning: This example uses the hydraulic domain, which will be removed in a future release. Find an equivalent example model that uses the isothermal liquid domain here: Power-Assisted Steering Mechanism. To convert models to the isothermal liquid domain, use the hydraulicToIsothermalLiquid tool.

Vacuum Booster

Model, parameterize, and test a vacuum booster. The model is used to generate the plot between applied and generated forces for the brake vacuum booster.

Vacuum Boosted Tandem Primary Cylinder

Model, parameterize, and test a vacuum boosted tandem primary cylinder. A model is used to generate the plot between the applied force and the generated pressures in the brake lines.

Vehicle HVAC System

Models the heating and cooling system of a passenger car. The cabin is represented as a volume of moist air exchanging heat with the external environment. The blower drives moist air through the evaporator, blend door, and heater core before returning to the cabin. The blend door controls the amount of air flow through the heater core. The recirculation door controls whether air is brought in from the external environment or from within the cabin.

MATLAB Command

You clicked a link that corresponds to this MATLAB command:

Run the command by entering it in the MATLAB Command Window. Web browsers do not support MATLAB commands.

Select a Web Site

Choose a web site to get translated content where available and see local events and offers. Based on your location, we recommend that you select: .

You can also select a web site from the following list

How to Get Best Site Performance

Select the China site (in Chinese or English) for best site performance. Other MathWorks country sites are not optimized for visits from your location.

Americas

- América Latina (Español)

- Canada (English)

- United States (English)

Europe

- Belgium (English)

- Denmark (English)

- Deutschland (Deutsch)

- España (Español)

- Finland (English)

- France (Français)

- Ireland (English)

- Italia (Italiano)

- Luxembourg (English)

- Netherlands (English)

- Norway (English)

- Österreich (Deutsch)

- Portugal (English)

- Sweden (English)

- Switzerland

- United Kingdom (English)