Build a Drivetrain Model

The example model in Drivetrain Model illustrates a typical drivetrain system that you can model with Simscape™ Driveline™ software. It also illustrates the key rules for connecting driveline blocks to each other and the dual roles of Simscape physical connection lines in driveline modeling. Within the Simscape mechanical domain:

The across variable is angular or linear velocity, depending on the type of mechanical ports you are connecting to, rotational or translational. Along any connection line, the velocity is the same.

Depending on the type of mechanical ports, you are connecting to, the through variable is torque or force. Torques and forces are conserved along a connection line and sum to zero at line branch points.

Before building and running the tutorial models, review these rules.

Driveline blocks feature mechanical conserving ports

and, in some cases, physical signal ports

and, in some cases, physical signal ports  . You can connect mechanical ports only to other mechanical

ports, and physical signal ports only to one another.

. You can connect mechanical ports only to other mechanical

ports, and physical signal ports only to one another.You cannot mix rotational and translational ports, or connect a mechanical conserving port to a physical signal port.

The physical connection lines interconnecting mechanical ports

represent driveline axes and enforce physical

relationships. Unlike physical signal and Simulink® lines, they do not represent signals or mathematical operations,

and they have no inherent directionality.

represent driveline axes and enforce physical

relationships. Unlike physical signal and Simulink® lines, they do not represent signals or mathematical operations,

and they have no inherent directionality.A driveline connection line represents an idealized massless and perfectly rigid spinning shaft or translating axis. A driveline connection line between two ports constrains the two driveline components that are connected to the line to rotate or translate at the same velocity.

You can branch mechanical connection lines. Connect the end of any branch of a mechanical connection line to a mechanical port

.

.Branching a driveline connection line modifies the physical constraints that it represents. All driveline components connected to the ends of a set of branched lines rotate or translate at the same velocity. For lines branched from a branch point, the sum of all torques or forces flowing in equals the sum of all torques or forces flowing out. How the torque or force is divided depends on the defining equations of the attached blocks in the rest of the system.

Mechanical connection lines satisfying the velocity constraint must have the same initial velocities.

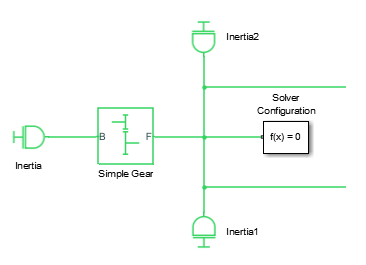

Branching Driveline Connection Lines

The Solver Configuration block in this example does not use any torque. It does share the angular velocity constraint from the branch point. Symbolically, the branching conditions on driveline connection lines are:

ω1 = ω2= ω3 ...

and

τ1 + τ2 + τ3 + ... = 0

The sign convention is that torques flowing in are positive. Like all driveline axes, these elements have no inherent directionality. Torque flow directions are defined by overall system equations during simulation.

Torque and motion are transferred through the driveline from some driveshafts to others. Certain Simscape Driveline blocks require explicit directionality and represent it by designating one driveline connector port as the input base (B) and the other as the output follower (F), or some equivalent pair. When required, positive relative motion of driveline axes or shafts is measured as follower relative to base.

Motion Is Absolute

Except when relative motion is explicitly required, all motion in Simscape Driveline and Simscape models is measured in implicit absolute coordinates. The Mechanical Rotational Reference and Mechanical Translational Reference blocks define the absolute zero velocity. If they are connected to a driveline axis, these blocks enforce this zero-motion state on that axis.